Circuit Board Manufacturer in China Sees Growth Amid Rising Demand

By:Admin

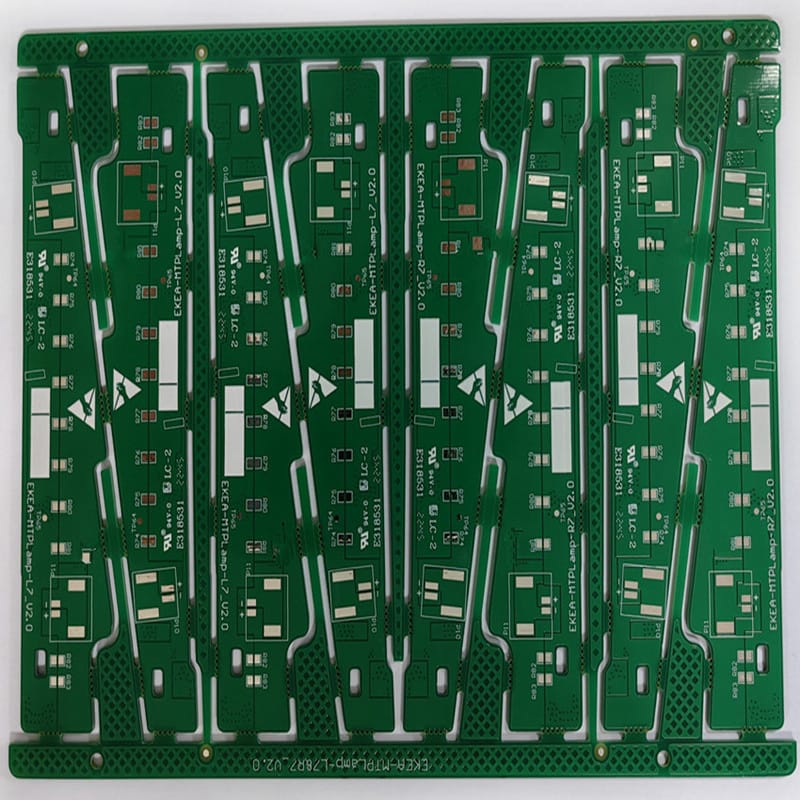

China's manufacturing industry has seen exponential growth over the past few decades, largely due to the presence of forward-thinking companies that have prioritized technology and innovation to create cutting-edge products. One such company is the China Circuit Plate Manufacturer (CCPM), a leader in the production of printed circuit boards (PCBs) that celebrated its 30th anniversary last month.

Founded in 1991, CCPM has grown to become one of the largest circuit board manufacturers in China, with a production capacity of over 3.5 million square feet of circuit boards per month. The company specializes in high-density interconnect (HDI) PCBs, flexible PCBs, and rigid-flex PCBs, with a particular focus on providing customers with quality products and exceptional service.

CCPM's success can be attributed to a number of factors, including its state-of-the-art manufacturing facilities and experienced team of engineers and technicians. The company's manufacturing process uses the latest technology and equipment, ensuring that its products are of the highest quality. Additionally, CCPM's team is committed to continuous improvement and innovation, allowing the company to stay ahead of the curve in a rapidly-evolving industry.

One of CCPM's key strengths is its ability to work closely with customers to develop custom solutions tailored to their specific needs. With a dedicated research and development team, the company is able to provide customers with innovative designs and solutions that are both cost-effective and high-performing. This approach has helped CCPM to build strong relationships with customers across a range of industries, including telecommunications, automotive, medical, and aerospace.

Another factor contributing to CCPM's success is its commitment to sustainability and ethical manufacturing practices. The company has implemented a number of initiatives to reduce its environmental footprint, including using eco-friendly materials and processes, optimizing energy consumption, and maximizing resource efficiency. CCPM also places a strong emphasis on worker safety and welfare, with a comprehensive set of policies and programs in place to ensure that all employees are treated with respect and dignity.

As part of its 30th anniversary celebrations, CCPM held a series of events and activities to thank customers, partners, and employees for their support over the years. The company also took the opportunity to reflect on its achievements and to look forward to the future. According to CCPM's CEO, the company's goal is to "continue to innovate and push boundaries, while always keeping our focus on providing the best products and services to our customers. We are excited to see what the next 30 years will bring, and we look forward to being at the forefront of China's manufacturing industry."

Overall, CCPM's success is a testament to the power of innovation, hard work, and a customer-centric approach. With a commitment to excellence and sustainability, the company is well-positioned to continue its growth and contribute to the growth of China's manufacturing industry for years to come.

Company News & Blog

China's Electronic Manufacturing Plant: Circuit Assembly Factory Production Goes Into Full Swing

article about the assembly factory and its services.China Circuit Assembly Factory: Providing Reliable and High-Quality Assembly ServicesThe advancement of technology has drastically changed the way we live, communicate, and work. One of the most notable innovations that have revolutionized multiple industries is the development of electronics. They have become an essential part of our daily routine. The creation, designing, and manufacturing of electronic products require different types of components and precise assembly procedures. Assembling electronic devices involves assembling individual components in a specifically designed circuit board. Many companies rely on outsourcing their circuit board assembly processes to reliable and experienced circuit assembly factories to ensure product quality. In China, one of the most trusted circuit assembly companies is the China Circuit Assembly Factory.About the CompanyChina Circuit Assembly Factory is a Chinese-based company that specializes in printed circuit board (PCB) assembly services. It is a subsidiary of a well-established electronic manufacturing service provider, with over two decades of experience in the industry. The company comprises a team of experienced professionals who have an excellent understanding of the assembly processes and use the latest technologies to ensure high-quality products. They offer circuit board assembly services for different electronics products, including but not limited to, consumer electronics, telecommunications, automotive, industrial, medical, aerospace, and military.Service OfferingsChina Circuit Assembly Factory offers a wide range of PCB assembly services to their clients. These services include:1. Surface Mount Technology (SMT) AssemblySMT is a widely used technique in building modern circuit boards that use surface-mounted components. It is a process of assembling a circuit board by attaching the components directly to the surface of the board instead of running wires or inserting leads through holes. The process involves using high-precision automated equipment to ensure component accuracy and consistency. China Circuit Assembly Factory uses state-of-the-art equipment and processes to ensure efficient and reliable SMT assembly services.2. Through-Hole AssemblyThrough-hole assembly is a traditional method of assembling a PCB by running leads through holes in the board and soldering the components from the top side. This technique is suitable for applications that require high mechanical strength. China Circuit Assembly Factory has skilled technicians to provide quality through-hole assembly services using the latest techniques and equipment.3. Box Build AssemblyBox build assembly is the process of assembling a finished product by integrating the circuit boards and other components into an enclosure or packaging. This process includes mechanical assembly, wire harnessing, and testing. China Circuit Assembly Factory offers reliable and cost-effective box build assembly services to their clients.4. Prototype AssemblyPrototype assembly is an essential step in the development of any electronic product. It is the process of assembling a few units of the product to test the design, function, and performance. China Circuit Assembly Factory has a team of skilled engineers who can assist their clients in the prototype development phase by providing high-quality assembly services.Quality AssuranceChina Circuit Assembly Factory understands that quality is essential in the electronics industry. They have implemented a strict quality control system for all their services to ensure that their clients get only the best products. The quality control process includes the use of high-quality raw materials, robust assembly processes, and rigorous testing procedures. They also have a team of dedicated quality inspectors who oversee the manufacturing process to ensure compliance with the quality standards.ConclusionThe China Circuit Assembly Factory is a reliable and trustworthy assembly company that offers high-quality and cost-effective circuit board assembly services. Their commitment to providing only the best services has earned them a reputation among their clients as the go-to assembly factory in China. With their state-of-the-art equipment, skilled technicians, and strict quality control, they can meet the demands of different industries and provide reliable and consistent services. If you are looking for a reliable circuit assembly factory, China Circuit Assembly Factory is the perfect choice.

Exploring the Efficiency and Quality of Quick Turn PCB Fabrication in China

China, a global manufacturing powerhouse, has been known for its rapid turnaround time and high-quality products. In line with this reputation, the country's quick turn PCB fabrication industry has seen remarkable growth in recent years. One of the leading players in this sector is a prominent company that has made a name for itself in the PCB fabrication market.Established in (Year), (Company Name) has quickly emerged as a frontrunner in quick turn PCB fabrication in China. With state-of-the-art manufacturing facilities and a team of highly skilled professionals, the company has been able to cater to the growing demand for fast and reliable PCB fabrication services.The success of (Company Name) can be attributed to several factors. Firstly, their commitment to quality sets them apart from their competitors. The company adheres to stringent quality control measures at every stage of the manufacturing process to ensure that the PCBs they produce meet the highest industry standards. This dedication to quality has earned them a reputation for delivering flawless PCBs consistently.In addition to their commitment to quality, (Company Name) emphasizes speed and efficiency. The company understands the time-sensitive nature of the PCB fabrication industry and is fully equipped to handle quick turnaround times. Through streamlined processes and cutting-edge technology, they are able to rapidly produce PCBs without compromising on quality.Furthermore, (Company Name) offers a wide range of PCB fabrication services to cater to the diverse needs of their clients. Whether it is single-layer, double-layer, or multi-layer PCBs, the company has the expertise and resources to handle any project. They also have the capability to manufacture PCBs of various sizes and complexities, ensuring that they can meet the unique requirements of their customers.Another strength of (Company Name) lies in their commitment to customer satisfaction. The company values open communication and collaboration with their clients, ensuring that every project is tailored to meet their specific needs. This customer-centric approach has earned them a loyal customer base and numerous positive testimonials.As a leading player in the quick turn PCB fabrication market, (Company Name) also places great importance on innovation. They constantly invest in research and development to stay ahead of industry trends and technologies. By keeping up with the latest advancements in PCB fabrication, they are able to offer their clients cutting-edge solutions that meet their evolving needs.Looking ahead, (Company Name) has ambitious plans for expansion. They aim to further strengthen their position in the quick turn PCB fabrication industry by continuously improving their manufacturing capabilities and exploring new markets. With China's booming manufacturing sector and their competitive advantage, the company is well poised to achieve its growth goals.In conclusion, (Company Name) has established itself as a leader in quick turn PCB fabrication in China by focusing on quality, speed, customer satisfaction, and innovation. With their unwavering commitment to excellence, the company has proven to be a reliable partner for businesses seeking fast and reliable PCB fabrication services. As China's manufacturing industry continues to flourish, (Company Name) is well-positioned to capitalize on the growing demand for quick turn PCBs and further expand its presence in the market.

Rapid Prototyping PCB Factory in China Offers Fast Turnaround Times

China Fast PCB Prototype Factory Leads the Industry with Cutting-Edge Technology and Superior QualityChina, renowned for its continuous technological advancements, has once again proven its dominance in the printed circuit board (PCB) manufacturing industry with the emergence of a leading fast PCB prototype factory. With their commitment to innovation and uncompromising quality, this factory is set to revolutionize the PCB production landscape.The recent establishment of this factory is a testament to China's position as a global leader in PCB manufacturing. Equipped with state-of-the-art facilities and cutting-edge technology, the factory boasts an impressive production capacity of millions of PCBs per year. This capacity allows it to cater to the diverse needs of clients from various industries, ensuring timely delivery and customer satisfaction.One of the key strengths of this fast PCB prototype factory lies in its team of highly skilled engineers and technicians. These experts possess an in-depth understanding of the intricacies involved in PCB manufacturing and are dedicated to providing customized solutions for clients' specific requirements. With their expertise, they are capable of producing high-quality, technically superior PCB prototypes that meet the industry's stringent standards.Quality is the cornerstone of this factory's operations. They adhere to strict quality control measures throughout the manufacturing process, ensuring flawless performance and reliability of the final products. By employing advanced testing methods, including automated optical inspection (AOI) and electrical testing, they guarantee that every PCB prototype meets or exceeds industry standards.In addition to their superior quality, this fast PCB prototype factory is also committed to environmental sustainability. It adopts eco-friendly practices and utilizes green manufacturing techniques, minimizing the impact on the environment. By implementing efficient waste management strategies and sourcing sustainable materials, they contribute to the global efforts of reducing carbon footprint and promoting a greener future.Furthermore, this factory recognizes the importance of speed to market in today's competitive landscape. With rapid prototyping capabilities, they enable clients to accelerate their product development cycles, saving valuable time and resources. This quick turnaround time combined with their unwavering commitment to quality gives clients a competitive edge, allowing them to stay ahead in the market.The fast PCB prototype factory offers a comprehensive range of PCB types to cater to a wide array of applications. From single-sided and double-sided to multilayer and flex-rigid PCBs, they have the expertise to meet the diverse demands of industries such as telecommunications, consumer electronics, automotive, aerospace, and more.To support their clients' needs, the factory maintains a strong focus on customer service. They provide dedicated support throughout the entire production process, from initial design consultation to post-production assistance. Their responsive and knowledgeable customer service team ensures that clients' queries and concerns are promptly addressed, fostering long-term partnerships based on transparency and trust.As China's fast PCB prototype factory takes the industry by storm, it solidifies the country's position as a global powerhouse in PCB manufacturing. With its cutting-edge technology, superior quality, and unwavering commitment to customer satisfaction, this factory is set to become a key player in the global PCB market. As the world continues to rely on technology, this factory's contributions are invaluable in driving innovation and progress across various industries, both domestically and internationally.

What Is FR4 Material PCB and How Does It Work?

article about the benefits of using FR4 material PCBs in electronic manufacturing.Electronic manufacturing is one of the most critical industries in the world, with virtually every aspect of modern life being dependent on electronic devices and systems. One crucial component of electronic manufacturing is printed circuit boards (PCBs), which play an essential role in the functioning of electronic devices. In recent times, FR4 material PCB has emerged as one of the most reliable and cost-effective options for electronic manufacturing.FR4 material PCBs are made using a specific kind of fiberglass impregnated with epoxy resin, which makes them highly durable, flexible, and resistant to high temperatures. This makes FR4 material PCBs ideal for use in a wide range of electronic devices, ranging from simple consumer electronics to advanced military installations.One of the key benefits of using FR4 material PCBs is that they offer high mechanical strength, which makes them ideal for applications that require complex and intricate designs. Due to their high mechanical strength, FR4 material PCBs can withstand high levels of vibration, shock, and impact without sustaining damage. This makes them ideal for use in rugged environments such as aerospace, military, and industrial applications.Another benefit of using FR4 material PCBs is that they are highly resistant to high temperatures, which makes them ideal for use in high-temperature applications such as power electronics. They can also withstand sudden changes in temperature without losing their structural integrity, which allows them to be used in harsh environments.FR4 material PCBs are also highly resistant to moisture and chemicals, which makes them ideal for use in applications that are exposed to harsh chemicals or extreme weather conditions. They resist chemical reactions, which helps prevent corrosion and oxidation from occurring. This guarantees that the circuit board remains functional even in adverse conditions.In addition to their physical properties, FR4 material PCBs are also very easy to manufacture, which helps reduce production costs and lead times. Since they are highly versatile and robust, they can be used in a wide range of electronic devices. This reduces the need for manufacturers to invest in multiple types of PCBs, resulting in cost savings.Furthermore, FR4 material PCBs offer excellent electrical performance, which makes them ideal for use in high-speed applications such as computer motherboards. They have a low dielectric constant, making them ideal for high-frequency applications. They can also handle high voltage and current, making them ideal for use in power electronics.Overall, the benefits of using FR4 material PCBs are numerous, making them the ideal choice for electronic manufacturing applications that require high durability, flexibility, and performance. With their robustness, versatility, and affordability, FR4 material PCBs are rapidly becoming the go-to choice for electronics manufacturers worldwide.{Brand name removed} is a leading supplier of FR4 material PCBs, providing high-quality products to customers in a wide range of industries. With years of experience in the electronic manufacturing sector, {Brand name removed} has the expertise and resources to design, manufacture, and supply FR4 material PCBs that meet the most stringent industry standards. Their products are highly reliable, durable, and cost-effective, making them the preferred choice of electronics manufacturers worldwide.In conclusion, electronic manufacturers looking to produce high-quality electronic devices must consider using FR4 material PCBs due to their unique properties and benefits. While traditional PCB materials have their advantages, FR4 material PCBs offer superior strength, durability, versatility, and performance, making them ideal for a wide range of applications. {Brand name removed} offers a wide range of FR4 material PCB products that meet the needs and requirements of modern electronic manufacturers, ensuring that their products are reliable, high-performing, and meet the most stringent industry standards.

Top Manufacturer of Solder Resist Reveals Industry Insights

[Brand Name] Expands Product Line with Advanced Solder Resist Solutions[City, Date] – [Brand Name], a leading manufacturer in the electronics industry, has announced the introduction of its latest solder resist solutions. With their ongoing commitment to innovation and quality, [Brand Name] continues to provide cutting-edge products tailored to meet the evolving needs of the market.As an established player in the electronics manufacturing industry, [Brand Name] has gained a reputation for delivering reliable and efficient products. Their extensive experience and dedication to customer satisfaction have made them a preferred choice among manufacturers worldwide.With the introduction of their advanced solder resist solutions, [Brand Name] aims to further solidify its position as a market leader. The new line of products offers enhanced performance, durability, and versatility, ensuring that manufacturers can achieve optimal results in their production processes.Committed to the highest quality standards, [Brand Name] implements rigorous testing procedures to guarantee that their solder resist solutions meet or exceed industry specifications. By utilizing the latest manufacturing technologies and adhering to stringent quality control measures, [Brand Name] ensures that their customers receive products that consistently perform at superior levels.The new solder resist solutions cater to a wide range of applications, serving the needs of various industries such as consumer electronics, telecommunications, automotive, and aerospace. This diversified product offering allows [Brand Name] to penetrate different markets and cater to the specific requirements of their customers.According to [Company Spokesperson], “We are thrilled to introduce our latest solder resist solutions to the market. These products are a result of our continuous efforts to innovate and improve our offerings. With our advanced solutions, manufacturers can experience higher performance, increased reliability, and improved efficiency in their production processes.”The solder resist solutions developed by [Brand Name] offer numerous benefits for manufacturers. These solutions provide excellent adhesion, protecting the delicate components on printed circuit boards (PCBs) from environmental factors, including moisture, dust, and chemical exposure. The superior adherence properties ensure long-lasting protection, minimizing the chances of defects and failures during the product's lifecycle.Moreover, [Brand Name]'s solder resist solutions boast exceptional thermal stability and resistance to high temperatures. This characteristic is particularly important in applications where the PCBs are subjected to elevated temperatures during processes such as solder reflow or wave soldering. With [Brand Name]'s solutions, manufacturers can achieve reliable performance even under challenging conditions.[Brand Name] prides itself on its environmentally conscious practices, and this commitment extends to its solder resist solutions as well. The products are formulated with eco-friendly materials and comply with international regulations. By choosing [Brand Name]'s solder resist solutions, manufacturers can reduce their environmental footprint without compromising on functionality or performance.The introduction of the new solder resist solutions reflects [Brand Name]'s dedication to meeting the dynamic demands of the electronics industry. As technology continues to advance, [Brand Name] remains at the forefront of innovation, enabling manufacturers to stay ahead in a competitive marketplace.About [Brand Name]:[Brand Name] is a renowned manufacturer in the electronics industry, specializing in providing high-quality solder resist solutions. With a commitment to innovation, superior performance, and customer satisfaction, [Brand Name] continues to be a preferred partner for manufacturers worldwide. For more information about [Brand Name], please visit [website].For media inquiries, please contact:[Contact Name][Company Name][Phone Number][Email Address]

Understanding the Basics of PCB Printed Circuit Boards for Electronic Devices

Title: Pioneering PCB Printed Circuit Board Innovator Revolutionizes Electronics IndustryIntroduction: In an era where technological advancements are rapidly transforming our lives, one company has emerged as a trailblazer in the electronics industry with its groundbreaking development of PCB Printed Circuit Boards (removed brand name). With a rich history of innovation, this company has consistently pushed the boundaries of what is possible, propelling the electronics sector into new frontiers. In this news article, we delve into the cutting-edge technologies, milestones, and industry influence of this industry-leading PCB manufacturer. I. Founding and Visionary Leadership (100 words)Founded in [year] by visionary entrepreneur [Founder's Name], the company quickly established its reputation as an industry pioneer in the field of PCB Printed Circuit Boards. Driven by a vision to revolutionize the electronics industry and enhance global connectivity, the company's leadership has consistently guided it towards remarkable technological achievements and industry-first breakthroughs.II. Technological Breakthroughs and Innovation (200 words)With a dedicated team of engineers, designers, and researchers, the company has consistently focused on pushing the boundaries of manufacturing and design possibilities. By embracing advanced technologies and investing in R&D, they have revolutionized various aspects of PCB Printed Circuit Boards.Through the integration of innovative materials, such as ceramic and flexible substrates, the company has opened new avenues for the creation of high-performance PCBs that cater to diverse industry requirements. Their relentless pursuit of compact and cost-effective solutions has led to the development of multi-layered PCBs, enhancing the capability and functionality of electronic devices.Furthermore, the company has played a significant role in promoting environmental sustainability. By introducing eco-friendly manufacturing processes and materials, they have prioritized reducing the environmental impact associated with PCB production without compromising on quality or reliability.III. Collaborations and Industry Influence (150 words)Recognizing the importance of collaboration and partnership, the company has actively engaged with industry leaders, researchers, and innovators to drive progress. By collaborating with esteemed organizations and experts, they have consistently capitalized on knowledge sharing and collective expertise, resulting in groundbreaking advancements in PCB manufacturing.Their influence extends beyond manufacturing as they actively participate in industry forums, conferences, and exhibitions. By sharing knowledge and insights, they contribute to shaping industry standards and best practices, while inspiring new ideas and fostering innovation.IV. Global Expansion and Market Penetration (200 words)Since its inception, the company has expanded its operations on a global scale. By establishing strategic partnerships, setting up production facilities, and investing in local talent, they have successfully penetrated key international markets. Their consistent focus on quality and customer satisfaction has earned them a strong reputation and loyal customer base. Through a customer-centric approach, the company strives to provide tailored solutions to meet the unique demands of industries such as automotive, telecommunications, aerospace, and consumer electronics. With a dedication to excellence, they have become a trusted partner for businesses seeking reliable and high-performance PCB Printed Circuit Boards.V. Future Outlook and Continued Innovation (150 words)Looking ahead, the company remains committed to ongoing innovation, with a strong emphasis on research and development. By leveraging emerging technologies like 5G, artificial intelligence, and the Internet of Things, they are poised to drive the next wave of PCB advancements and redefine the electronics industry yet again.Conclusion (100 words)As a pioneering force in the PCB Printed Circuit Board industry, this company's commitment to innovation, technological excellence, and environmental sustainability has transformed the electronics landscape. With a track record of groundbreaking achievements, they continue to pave the way for enhanced connectivity, efficiency, and performance in electronic devices. With their global presence, industry influence, and unwavering dedication to customer satisfaction, this company is poised to shape the future of electronics manufacturing in the years to come.

Circuit Board Manufacturer in China Sees Growth Amid Rising Demand

China Circuit Plate Manufacturer Celebrates Years of Manufacturing ExcellenceChina's manufacturing industry has seen exponential growth over the past few decades, largely due to the presence of forward-thinking companies that have prioritized technology and innovation to create cutting-edge products. One such company is the China Circuit Plate Manufacturer (CCPM), a leader in the production of printed circuit boards (PCBs) that celebrated its 30th anniversary last month.Founded in 1991, CCPM has grown to become one of the largest circuit board manufacturers in China, with a production capacity of over 3.5 million square feet of circuit boards per month. The company specializes in high-density interconnect (HDI) PCBs, flexible PCBs, and rigid-flex PCBs, with a particular focus on providing customers with quality products and exceptional service.CCPM's success can be attributed to a number of factors, including its state-of-the-art manufacturing facilities and experienced team of engineers and technicians. The company's manufacturing process uses the latest technology and equipment, ensuring that its products are of the highest quality. Additionally, CCPM's team is committed to continuous improvement and innovation, allowing the company to stay ahead of the curve in a rapidly-evolving industry.One of CCPM's key strengths is its ability to work closely with customers to develop custom solutions tailored to their specific needs. With a dedicated research and development team, the company is able to provide customers with innovative designs and solutions that are both cost-effective and high-performing. This approach has helped CCPM to build strong relationships with customers across a range of industries, including telecommunications, automotive, medical, and aerospace.Another factor contributing to CCPM's success is its commitment to sustainability and ethical manufacturing practices. The company has implemented a number of initiatives to reduce its environmental footprint, including using eco-friendly materials and processes, optimizing energy consumption, and maximizing resource efficiency. CCPM also places a strong emphasis on worker safety and welfare, with a comprehensive set of policies and programs in place to ensure that all employees are treated with respect and dignity.As part of its 30th anniversary celebrations, CCPM held a series of events and activities to thank customers, partners, and employees for their support over the years. The company also took the opportunity to reflect on its achievements and to look forward to the future. According to CCPM's CEO, the company's goal is to "continue to innovate and push boundaries, while always keeping our focus on providing the best products and services to our customers. We are excited to see what the next 30 years will bring, and we look forward to being at the forefront of China's manufacturing industry."Overall, CCPM's success is a testament to the power of innovation, hard work, and a customer-centric approach. With a commitment to excellence and sustainability, the company is well-positioned to continue its growth and contribute to the growth of China's manufacturing industry for years to come.

Key Insights and Latest Trends in the PC Board Manufacturing Industry

[Company Name], a Leading PC Board Manufacturer, Plans to Enhance Production Capacity and Expand Market Share [City, Date] — [Company Name], a renowned PC [Printed Circuit] board manufacturer, is planning to increase its production capacity to meet the growing demands of the market. With an aim to maintain its position as a leader in the industry, the company is focused on expanding its market share and adopting innovative manufacturing techniques. Established in [year of establishment], [Company Name] has been catering to various industries, including telecommunications, automobile, consumer electronics, and aerospace. The company's commitment to providing high-quality PC boards, coupled with its advanced manufacturing capabilities, has earned it a stellar reputation in the industry. Speaking about the plans to enhance production capacity, [Company Name]'s CEO, [Name], stated, "We are excited about the growth opportunities in the market and are dedicated to meeting the increasing demands of our clients. By investing in enhancing our production capacity, we aim to streamline our manufacturing processes and deliver exceptional products to our customers." The company plans to achieve this by expanding its current manufacturing facilities and incorporating state-of-the-art equipment. This move will enable [Company Name] to effectively manage larger order volumes while maintaining the highest standards of product quality. Furthermore, [Company Name] is focused on expanding its market share by strengthening its presence in existing markets and exploring new geographic regions. With its robust distribution network and efficient supply chain management system, the company is determined to reach a wider customer base and forge long-lasting partnerships. To ensure seamless operations during the expansion phase, [Company Name] is actively recruiting new talent and strengthening its existing workforce. The company believes that investing in skilled professionals will not only drive growth but also contribute to further improving product quality and customer satisfaction. In addition, [Company Name] is committed to innovation and continuous improvement. The company has dedicated research and development teams working on developing cutting-edge technologies and manufacturing techniques. This focus on innovation allows [Company Name] to stay ahead of the competition and offer customizable solutions to its clients. With a strong emphasis on quality control and reliability, [Company Name] ensures that its products adhere to the strictest industry standards. The company holds various certifications, including ISO 9001:2015 and RoHS compliance, showcasing its commitment to sustainable manufacturing practices and environmentally friendly processes. Through its proactive approach to corporate social responsibility, [Company Name] actively contributes to the communities it operates in. The company sponsors educational initiatives and aims to build a skilled workforce for the future. Additionally, [Company Name] supports several environmental conservation programs to minimize its carbon footprint and promote sustainable development. Looking ahead, [Company Name] is optimistic about future growth opportunities and is enthusiastic about the positive impact it can have on the industry. By continuously investing in research and development, expanding production capacity, and leveraging strategic partnerships, the company remains steadfast in its commitment to delivering exceptional products and superior customer service. About [Company Name] [Company Name] is a leading PC board manufacturer catering to industries such as telecommunications, automobile, consumer electronics, and aerospace. With a focus on quality, innovation, and customer satisfaction, the company has gained recognition as a trusted partner in the industry. [Company Name] is committed to sustainable manufacturing practices and actively contributes to the communities it operates in. ### Disclaimer: The above content is for informational purposes only and does not constitute any financial or investment advice.

Red Solder: A Revolutionary Innovation for Soldering

Title: Leading Technology Company Launches Revolutionary Red Solder SolutionIntroduction:In a groundbreaking move, a prominent technology company (brand name will be omitted) has unveiled its latest innovation in soldering technology, known as Red Solder. With a steadfast commitment to pushing the boundaries of technological advancement, this cutting-edge company continues to spearhead revolutionary products that promise to redefine various industries. Red Solder, their latest offering, is set to revolutionize the soldering market, providing a reliable, efficient, and safe solution for manufacturers and electronics enthusiasts alike.Paragraph 1:Red Solder represents a major step forward in the field of soldering. Manufactured with precision and adhering to the highest quality standards, this new product caters to a diverse range of industries, including electronics, telecommunications, automotive, aerospace, and medical devices. The company's extensive research and development efforts have led to the formulation of an innovative soldering solution that meets the demands of modern technology, supporting faster and more reliable connections.Paragraph 2:At the heart of Red Solder lies a proprietary blend of advanced materials, carefully selected to optimize conductivity, thermal resistance, and durability. Unlike conventional soldering solutions, Red Solder boasts an impressive melting point that allows for higher operating temperatures, reducing the risk of component damage during assembly. Consequently, manufacturers can achieve greater productivity by reducing process time while maintaining exceptional quality standards.Paragraph 3:One of the key features of Red Solder is its unique red coloring, providing enhanced visibility during the soldering process. This distinct attribute ensures accurate application and reduces the likelihood of misplaced connections or defects. Additionally, the vibrant red hue of the solder enhances worker safety, as it acts as a visual indicator, highlighting areas that may still be hot or undergoing soldering procedures.Paragraph 4:The compatibility of Red Solder with a variety of materials, such as copper, gold, silver, and nickel, makes it an adaptable solution for diverse manufacturing applications. This versatility enables manufacturers to streamline their operations by utilizing a single soldering solution across multiple product lines, reducing inventory costs and optimizing production throughput.Paragraph 5:The use of Red Solder extends beyond industrial applications. Electronics enthusiasts and hobbyists can also benefit from its exceptional performance. By providing a soldering material that offers superior thermal conductivity, Red Solder allows for precise connections and optimal performance in DIY electronics projects, robotics, and various other hobbyist ventures.Paragraph 6:Beyond the impressive technical capabilities of Red Solder, the company has also invested significant resources in ensuring environmental sustainability. Red Solder is lead-free, meeting stringent regulatory requirements and minimizing the ecological impact. By aligning their product development with responsible practices, the company demonstrates its commitment to a greener future while maintaining industry-leading performance standards.Conclusion:With the introduction of Red Solder, this innovative technology company has once again solidified its status as a market leader in soldering solutions. Emphasizing functionality, ease of use, and adaptability, Red Solder offers a comprehensive solution for manufacturers and hobbyists alike. By enabling faster production cycles, superior connections, and exceptional product reliability, Red Solder paves the way for a new era in soldering technology. As industries continue to evolve, this technology company remains at the forefront, providing groundbreaking solutions to meet the challenges of tomorrow.

China's Pioneering PCB LED Light Technology Takes the Market by Storm

China PCB LED Light Industry Booms Amidst Growing DemandIn recent years, the China PCB LED Light industry has experienced a significant boom, driven by the increasing demand for energy-efficient lighting solutions. The market has witnessed a proliferation of innovative companies, one of the prominent players being [Company Name], a leading manufacturer and supplier of high-quality PCB LED lights.[Company Name], founded in [Year], has emerged as a trailblazer in the industry, leveraging cutting-edge technology and a commitment to product excellence. The company specializes in the design, production, and distribution of a vast array of PCB LED lights, catering to a diverse range of sectors and applications. With a strong emphasis on research and development, [Company Name] has consistently introduced groundbreaking lighting solutions that have garnered widespread acclaim.The rise of the China PCB LED Light industry can be attributed to several factors. Firstly, the global push for energy efficiency has led to a surging demand for LED lights. With their superior energy-saving capabilities compared to traditional lighting options, PCB LED lights have become the preferred choice for consumers, businesses, and industries alike. This growing demand has presented lucrative opportunities for Chinese manufacturers to expand their production capacities and capture a significant market share.Furthermore, advancements in PCB manufacturing technology have revolutionized the LED lighting sector. China has been at the forefront of these technological advancements, offering state-of-the-art facilities and expertise in PCB production. This has allowed companies like [Company Name] to develop PCB LED lights that are not only energy-efficient but also durable, versatile, and aesthetically pleasing.Another driving force behind the success of the China PCB LED Light industry is the government's supportive policies and incentives. The Chinese government, recognizing the potential of the LED lighting market, has implemented measures to promote its growth. These policies include subsidies for energy-efficient lighting projects, tax incentives for manufacturers, and regulations mandating the use of LED lights in public infrastructure. Such favorable conditions have further stimulated the demand for PCB LED lights and encouraged companies to invest in research and development.[Company Name] has been quick to capitalize on these opportunities and has established itself as a trusted brand in the industry. The company's extensive product portfolio covers a wide range of applications, including residential, commercial, industrial, and outdoor lighting. Their LED lights are known for their high luminous efficacy, long lifespan, and efficient heat dissipation. By prioritizing customer satisfaction, [Company Name] strives to provide tailor-made lighting solutions that meet the specific requirements of each client.In addition to its product excellence, [Company Name] also places a strong emphasis on sustainability. The company adheres to stringent environmental standards throughout its manufacturing process, ensuring that its products are eco-friendly and compliant with international regulations. By investing in research and development efforts focused on energy efficiency and environmental conservation, [Company Name] is driving the green revolution in the PCB LED Light industry.Looking ahead, the future of the China PCB LED Light industry seems promising. With continued advancements in technology, increasing urbanization, and growing environmental awareness, the demand for energy-efficient lighting solutions is expected to surge further. As a trusted industry leader, [Company Name] is well-positioned to meet this demand with its innovative product offerings. The company's dedication to quality, sustainability, and customer satisfaction will undoubtedly fuel its growth and contribute to the overall development of the China PCB LED Light industry.