Fast PCB Assembly Services for Efficient Electronic Manufacturing

By:Admin

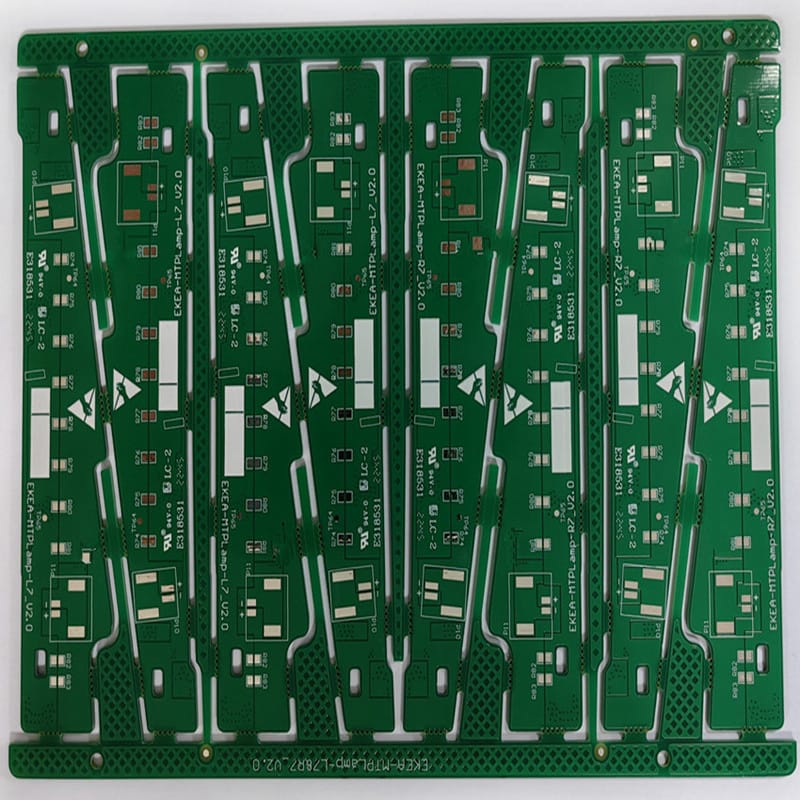

With PCBs playing such a crucial role in modern technology, it's critical to have a reliable and reputable manufacturing partner to produce high-quality and durable PCBs. That's where Quick Turn PCB Assembly Manufacturer comes in as a leading player in the PCB manufacturing industry.

Quick Turn PCB Assembly Manufacturer has been a reliable choice for many original equipment manufacturers (OEMs), electronics distributors, and engineering firms for many years. The company offers fast printed circuit board manufacturing and assembly services, allowing OEMs to get their products to market quickly and efficiently.

The company's high-quality PCBs are designed and produced to meet the highest industry standards. Quick Turn PCB Assembly Manufacturer targets a broad range of industries, including aerospace, automotive, medical devices, telecommunications, and consumer electronics.

One of the key factors that set Quick Turn PCB Assembly Manufacturer apart from others in the industry is its commitment to customer satisfaction. The company's team of experts works closely with their clients to understand their needs and expectations, providing customized solutions that meet specific requirements.

The company's rapid prototyping capability is another area where they have established themselves as a reliable and top-quality PCB manufacturer. Time is a critical factor when developing electronic products, and Quick Turn PCB Assembly Manufacturer recognizes that. They provide quick turn PCB prototypes with fast turnaround times, enabling clients to test and validate the design of their products.

Quick Turn PCB Assembly Manufacturer has a state-of-the-art facility equipped with advanced machinery and equipment to ensure precision and consistency in PCB production. The company's production process follows strict quality control standards, ensuring every PCB that leaves their facility meets or exceeds their clients' expectations.

The company offers a wide range of PCB manufacturing services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly. Quick Turn PCB Assembly Manufacturer's PCBs come in various sizes and configurations, making it easy for clients to find the right PCB for their specific application.

In addition to PCB manufacturing, Quick Turn PCB Assembly Manufacturer also offers value-added services such as design for manufacturability (DFM) assessment, component sourcing, and functional testing. The company's comprehensive services make them a one-stop-shop solution for clients, helping them streamline their production process and reduce manufacturing costs.

Overall, Quick Turn PCB Assembly Manufacturer's commitment to quality, reliability, and customer satisfaction has made them an industry leader in the PCB manufacturing space. With their focus on fast turnaround times, fast prototyping, and customized solutions, the company is well-positioned to continue its growth and expand its reach in the years to come.

Company News & Blog

Quick and Efficient PCB Prototypes: A Game-Changer in Electronics Development

In today's fast-paced world, time is of the essence. A delay in any part of a business process can lead to a significant loss of time and revenue. When it comes to designing electronic prototypes, PCB's or Printed Circuit Boards play a crucial role. These prototypes form a key component of any electronic gadget, from mobile phones and laptops to medical equipment and satellite systems. Designing PCB's to match the requirements of a project is no easy feat. It requires a high level of skill, expertise, and most importantly, time.Here lies the importance of Fast PCB Prototypes, a company that specializes in quick, reliable and accurate PCB prototyping services. The company prides itself on providing clients with top-notch PCB PCB fabrication, assembly, and testing services at lightning-fast speeds. Their extensive range of services includes PCB design, layout, assembly, and manufacturing, and they can accommodate both low volume and high-volume production runs.Fast PCB Prototypes' unique selling proposition is their focus on reducing the prototyping time for their clients, without compromising on quality. How do they do it? "At Fast PCB Prototypes, we leverage our experience and expertise to streamline the PCB production process without sacrificing quality," says the company spokesperson. "We use advanced software and machinery that allows us to provide fast and accurate prototyping services to our clients, ensuring they receive their PCB prototypes on time."The company offers a broad range of PCB prototyping services that cater to various industries. They provide both single and multilayer PCBs, and can accommodate sizes that range from small PCBs to large PCBs with up to 20 layers. Fast PCB Prototypes' customers span across a broad spectrum of industries, including aerospace, defense, medical, and industrial sectors."Our focus is always on delivering quality PCB prototypes that meet the needs of our customers," says the spokesperson. "We understand the unique requirements of each client, and we work hard to ensure that all their needs are met. Our team of experienced technicians and engineers works 24/7 to provide fast, accurate, and reliable PCB prototyping services."Fast PCB Prototypes prides itself on its state-of-the-art production facility, which uses advanced equipment to produce high-quality PCB prototypes. The company places a strong emphasis on quality control, and all PCBs undergo rigorous testing to ensure they meet the highest industry standards. The company follows strict procedures to ensure the PCB designs are free from errors and are properly optimized for production."Customers can rest assured that their PCB prototypes will be in good hands with us," says the spokesperson. "We have invested heavily in our production facility and have a team of experienced professionals who are dedicated to ensuring that every project is a success."Fast PCB Prototypes is committed to providing its customers with a reliable, affordable, and fast PCB prototyping service. Whether a client requires a single PCB prototype or a high-volume production run, the company is dedicated to providing a solution that meets their needs. With a track record of success and customer satisfaction, Fast PCB Prototypes is the ideal choice for any company that requires high-quality PCB prototyping services.

Fast PCB Assembly Services for Efficient Electronic Manufacturing

In today's fast-paced and ever-changing world, technology plays a significant role in revolutionizing the way we live and interact with each other. One of the most critical components of modern technology is printed circuit boards (PCBs). These small, yet complex devices are found in almost every electronic device we use and rely on every day, from smartphones to computers, televisions, and even medical equipment.With PCBs playing such a crucial role in modern technology, it's critical to have a reliable and reputable manufacturing partner to produce high-quality and durable PCBs. That's where Quick Turn PCB Assembly Manufacturer comes in as a leading player in the PCB manufacturing industry.Quick Turn PCB Assembly Manufacturer has been a reliable choice for many original equipment manufacturers (OEMs), electronics distributors, and engineering firms for many years. The company offers fast printed circuit board manufacturing and assembly services, allowing OEMs to get their products to market quickly and efficiently.The company's high-quality PCBs are designed and produced to meet the highest industry standards. Quick Turn PCB Assembly Manufacturer targets a broad range of industries, including aerospace, automotive, medical devices, telecommunications, and consumer electronics.One of the key factors that set Quick Turn PCB Assembly Manufacturer apart from others in the industry is its commitment to customer satisfaction. The company's team of experts works closely with their clients to understand their needs and expectations, providing customized solutions that meet specific requirements.The company's rapid prototyping capability is another area where they have established themselves as a reliable and top-quality PCB manufacturer. Time is a critical factor when developing electronic products, and Quick Turn PCB Assembly Manufacturer recognizes that. They provide quick turn PCB prototypes with fast turnaround times, enabling clients to test and validate the design of their products.Quick Turn PCB Assembly Manufacturer has a state-of-the-art facility equipped with advanced machinery and equipment to ensure precision and consistency in PCB production. The company's production process follows strict quality control standards, ensuring every PCB that leaves their facility meets or exceeds their clients' expectations.The company offers a wide range of PCB manufacturing services, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly. Quick Turn PCB Assembly Manufacturer's PCBs come in various sizes and configurations, making it easy for clients to find the right PCB for their specific application.In addition to PCB manufacturing, Quick Turn PCB Assembly Manufacturer also offers value-added services such as design for manufacturability (DFM) assessment, component sourcing, and functional testing. The company's comprehensive services make them a one-stop-shop solution for clients, helping them streamline their production process and reduce manufacturing costs.Overall, Quick Turn PCB Assembly Manufacturer's commitment to quality, reliability, and customer satisfaction has made them an industry leader in the PCB manufacturing space. With their focus on fast turnaround times, fast prototyping, and customized solutions, the company is well-positioned to continue its growth and expand its reach in the years to come.

Top Halogen Free PCB Manufacturers Empowering Sustainable Electronics Manufacturing

OEM Halogen Free PCB Manufacturers is a leading provider of printed circuit board solutions for a wide range of applications. With decades of experience in the industry, the company has built a reputation for quality, reliability, and innovation. Recently, OEM Halogen Free PCB Manufacturers has expanded its capabilities to include the production of halogen-free PCBs, which offer a safer and more environmentally friendly alternative to traditional PCBs.Halogen-free PCBs are becoming increasingly popular in the electronics industry because they do not contain halogenated flame retardants, which can release toxic fumes when exposed to high temperatures. This makes them safer for use in a variety of applications, including consumer electronics, automotive systems, and medical devices. In addition, halogen-free PCBs are more environmentally friendly because they do not contribute to the pollution of water and air.OEM Halogen Free PCB Manufacturers has invested in new equipment and technology to produce high-quality halogen-free PCBs that meet the latest industry standards. The company uses a variety of materials, including FR-4, CEM-3, and high-speed laminates, to design and manufacture custom PCBs that meet the unique needs of each customer. OEM Halogen Free PCB Manufacturers also offers a range of services, including PCB assembly, testing, and inspection, to ensure that each product meets the highest standards of quality and reliability.One of the key advantages of working with OEM Halogen Free PCB Manufacturers is the company's commitment to customer service. From the initial design consultation to the final delivery of the finished PCBs, the company provides personalized support and guidance to ensure that each customer is fully satisfied with the end result. OEM Halogen Free PCB Manufacturers also offers quick turnaround times and competitive pricing to help customers stay within their budgets and timelines.In addition to halogen-free PCBs, OEM Halogen Free PCB Manufacturers offers a range of other PCB solutions, including rigid PCBs, flex PCBs, and metal core PCBs. Each product is custom-designed and manufactured to meet the specific requirements of the customer's application. OEM Halogen Free PCB Manufacturers also has experience working with a variety of industries, including aerospace, defense, telecommunications, and more.Overall, OEM Halogen Free PCB Manufacturers is a trusted and reliable partner for all of your printed circuit board needs. Whether you need a halogen-free PCB or a custom-designed PCB for a specific application, the company's experienced team of engineers and technicians can provide the expertise and support you need to achieve your goals. With a commitment to quality, reliability, and innovation, OEM Halogen Free PCB Manufacturers is poised to lead the way in the electronics industry for years to come.

Understanding the Importance and Advantages of UL PCBs in China

China UL PCB Manufacturer: Leading the Way in Quality and InnovationIn the world of electronics manufacturing, quality is of utmost importance. Achieving the highest standards in the production of Printed Circuit Boards (PCBs) requires not only cutting-edge technology but also a commitment to continuous improvement. China UL PCB Manufacturer, a renowned industry leader, has proven time and again their dedication to providing superior products and services. With an impressive track record and a client base that spans the globe, this company is at the forefront of innovation and reliability in the PCB manufacturing industry.Founded in 2003, China UL PCB Manufacturer has established itself as a powerhouse in the competitive electronics market. With a state-of-the-art manufacturing facility, equipped with the latest machinery and a team of highly skilled professionals, they are capable of producing a wide range of UL certified PCBs to meet the diverse needs of their clients. The company prides itself on offering a comprehensive suite of services, including design, prototyping, manufacturing, and assembly, ensuring a seamless and efficient production process.One of the key factors that sets China UL PCB Manufacturer apart from its competitors is their unwavering commitment to quality. With certifications from reputable organizations such as Underwriters Laboratories (UL), they adhere strictly to international quality standards. UL certification ensures that their PCBs are manufactured using the best practices, materials, and components, resulting in products that are safe, reliable, and durable. This commitment to quality has earned China UL PCB Manufacturer a solid reputation among their clients, who rely on them for the most critical and demanding applications.Furthermore, China UL PCB Manufacturer recognizes that innovation is crucial to staying ahead in the rapidly evolving electronics industry. They invest heavily in research and development, constantly exploring new technologies and processes to enhance the performance and functionality of their PCBs. By leveraging cutting-edge techniques, such as HDI (High-Density Interconnect) and multilayer PCB construction, they are able to produce boards with higher circuit density, smaller form factors, and improved signal integrity.Aside from their technological advancements, China UL PCB Manufacturer also places great emphasis on providing exceptional customer service. Their dedicated team of engineers and support staff work closely with clients throughout the entire manufacturing process, fostering strong relationships and ensuring that all specifications and requirements are met to the highest degree of satisfaction. With a commitment to on-time delivery and prompt communication, they strive to exceed customer expectations at every opportunity.Global demand for PCBs continues to grow, and China UL PCB Manufacturer is well-positioned to meet this increasing market need. Their reputation for excellence, coupled with their competitive pricing, has allowed them to establish a strong presence not only in their domestic market but also in international markets, including North America, Europe, and Asia-Pacific. With an ever-expanding client base, partnerships with leading companies, and a reputation for delivering on their promises, China UL PCB Manufacturer is poised for continued success.In conclusion, China UL PCB Manufacturer has emerged as a leader and trailblazer in the field of PCB manufacturing. Their unwavering commitment to quality, continuous innovation, and exceptional customer service have propelled them to the forefront of the industry. With their state-of-the-art facility, advanced manufacturing techniques, and a team of dedicated professionals, they are equipped to handle the most demanding projects, ensuring reliable and high-performance PCBs for a rapidly advancing electronics market. As the demand for quality and technologically advanced PCBs continues to soar, China UL PCB Manufacturer remains the go-to choice for clients seeking reliable products and exceptional service.

Essential Guidelines for Efficient Electrical PCB Assembly and Manufacturing Revealed

Title: Revolutionizing the Electrical Industry: Cutting-edge PCB InnovationsIntroduction:In recent years, the electrical industry has witnessed unprecedented advancements, thanks to the tireless efforts of innovative companies. One such company, renowned for offering cutting-edge solutions, has unveiled their latest breakthrough in electrical Printed Circuit Board (PCB) technology. Their groundbreaking development promises to revolutionize multiple sectors and drive innovation forward. In this article, we delve into the unparalleled capabilities of this new Electrical PCB, explore its potential applications, and highlight the company's commitment to driving progress.State-of-the-art Electrical PCB:The newly introduced Electrical PCB has been designed with meticulous attention to detail, incorporating state-of-the-art technology that surpasses industry standards. Pioneering the field of printed circuit boards, this innovation is set to redefine reliability, performance, and efficiency within the electrical industry.Key Features and Advancements:1. Enhanced Power Efficiency:The advanced design of the Electrical PCB minimizes energy consumption without compromising performance. Through meticulous engineering, the company has successfully developed a circuit board that provides improved power distribution, reducing wastage and optimizing overall efficiency.2. Compact Design:The new Electrical PCB boasts a significantly smaller form factor, enhancing its versatility for a wide array of applications. The compact design not only saves valuable space but also streamlines manufacturing processes, reducing costs and time.3. High-Speed Data Transmission:The Electrical PCB has been optimized with high-speed data transmission capabilities, catering to the demanding needs of modern electrical systems. This cutting-edge feature enables seamless communication and connectivity, ensuring real-time data transfer between components and devices.4. Enhanced Durability:Durability is a key focus of this innovative Electrical PCB. The company has invested considerable resources in research and development, incorporating robust materials and manufacturing techniques that offer enhanced resistance to environmental factors such as moisture, corrosion, and extreme temperatures. This empowers industries to rely on the PCB for longer lifespans, reducing maintenance costs and downtime.5. Customizability:Recognizing the diverse requirements of different industries, the company's Electrical PCB is highly customizable. Tailored to meet specific needs, the PCB can be modified to fit various applications, ensuring seamless integration and compatibility across different electrical systems and devices.Potential Applications:From consumer electronics to industrial automation and renewable energy, the potential applications of this revolutionary technology are vast. The Electrical PCB's versatility opens doors for numerous industries seeking innovative solutions to their electrical challenges.1. Consumer Electronics:With its compact design, high-speed data transmission, and enhanced power efficiency, the Electrical PCB can be seamlessly integrated into smartphones, tablets, laptops, and other portable electronic devices. This innovation paves the way for smaller, more powerful, and energy-efficient consumer electronics.2. Automotive Industry:Enhanced durability and customizability make the Electrical PCB an attractive solution for the automotive industry. With increasing demands for electric vehicles, this groundbreaking technology ensures improved reliability, safety, and performance.3. Renewable Energy:The Electrical PCB's power efficiency and compact design offer significant advantages in renewable energy systems. This technology can facilitate efficient power conversion, making it ideal for solar panels, wind turbines, and energy storage systems.Company Commitment to Innovation:The company behind this monumental Electrical PCB breakthrough has a long-standing commitment to innovation and progress. Through ongoing research and development, they strive to push the boundaries of what is possible in the electrical industry. Their investment in cutting-edge technologies and dedication to customer satisfaction has solidified their position as a leader in the field.Conclusion:In a world where technological advancement is the driving force behind progress, the introduction of the Electrical PCB revolutionizes the electrical industry. With its groundbreaking features, including enhanced power efficiency, compact design, high-speed data transmission, and customizability, this innovation facilitates growth and transformation across various sectors. As this company continues to defy conventions and push the boundaries of technology, we can expect further groundbreaking developments in the future.

Leading PCB Manufacturing Facility in China Receives UL Certification

Title: Leading Chinese PCB Manufacturer Achieves UL Certification for Enhanced Quality and ReliabilityIntroduction:In an impressive feat of technological advancement and quality control, China PCB UL Factory, one of the country's leading printed circuit board manufacturing facilities, has recently achieved UL certification. This recognition underscores the company's commitment to providing top-notch products while reinforcing its position as a trusted partner for diverse industries such as automotive, telecommunications, consumer electronics, and more. With this new certification, China PCB UL Factory aims to further establish itself as a global leader in the PCB manufacturing industry.Body:1. The Road to UL Certification:China PCB UL Factory has continuously invested in cutting-edge technology and innovative manufacturing processes, enabling the company to produce high-quality PCBs that meet the stringent standards set by UL. The certification process involved rigorous assessments conducted by UL experts, evaluating factors such as design, material selection, manufacturing processes, and product performance. China PCB UL Factory successfully met all the necessary criteria, demonstrating its dedication to excellence.2. Advantages of UL Certification:Obtaining UL (Underwriters Laboratories) certification is no small accomplishment and speaks to a company's commitment to safety, reliability, and environmental sustainability. The UL mark instills trust in customers and reassures them that the products offered have been thoroughly tested and meet the highest industry standards. China PCB UL Factory's certification contributes to the company's reputation for top-tier quality, opening doors to new business opportunities and collaborations with global partners.3. Enhanced Product Reliability:UL certification signifies China PCB UL Factory's ability to manufacture products that adhere to strict quality control methodologies. The rigorous testing and auditing procedures conducted during UL assessments ensure that the PCBs not only meet performance benchmarks but also comply with safety regulations. By acquiring UL certification, the factory has bolstered its reputation for delivering reliable and durable PCBs, crucial components for various industries.4. Benefits for Collaborative Industries:China PCB UL Factory's achievement of UL certification offers many advantages to industries that rely on high-quality PCBs. The automotive sector, for instance, often demands exceptional performance and reliability in circuit boards used in electronic control units, sensors, and infotainment systems. With UL certification, China PCB UL Factory can position itself as a preferred PCB supplier for automotive manufacturers, enhancing its portfolio and expanding its global market share.5. Commitment to Environmental Responsibility:UL certification extends beyond product reliability; it also emphasizes a company's adherence to environmental safety protocols. China PCB UL Factory's compliance with UL standards underscores its commitment to minimizing environmental impact. The factory optimizes its manufacturing processes to reduce waste, supports the responsible disposal of hazardous materials, and promotes energy-efficient technologies. By prioritizing sustainable practices in PCB production, the company aligns itself with environmentally conscious partners and businesses.6. Market Competitiveness and Growth Prospects:The UL certification places China PCB UL Factory among an elite group of manufacturers that have met globally recognized standards for quality and safety. This achievement strengthens the company's position in the highly competitive global PCB market, enabling it to attract customers who prioritize reliability and adhere to stringent industry regulations. By capitalizing on its UL certification, China PCB UL Factory can explore new partnerships and expand its footprint in emerging sectors, such as Internet of Things (IoT), artificial intelligence (AI), and renewable energy.7. Future Outlook and Continued Excellence:Obtaining UL certification serves as a critical milestone in China PCB UL Factory's growth journey, but it is only the beginning of the company's commitment to continuous improvement. The factory plans to invest further in research and development to stay at the forefront of technological advancements, ensuring that its PCBs are compatible with evolving industry needs. By prioritizing customer satisfaction and emphasizing consistent quality, China PCB UL Factory strives to solidify its standing as a trusted PCB manufacturer worldwide.Conclusion:China PCB UL Factory's recent achievement of UL certification highlights its unwavering dedication to producing high-quality, reliable, and environmentally sustainable PCBs. This significant accomplishment positions the factory as a preferred partner for industries seeking superior electronic solutions. Through continued innovation and customer-centric practices, China PCB UL Factory is poised to further enhance its market competitiveness and drive the growth of the global PCB manufacturing industry.

Understanding the Different Classifications of PCBs and How They Impact Electronics Manufacturing

Title: Advanced Pcb Classification Technology Revolutionizes Electronics IndustryIntroduction (100 words):In an era driven by technological advancements, the electronics industry has witnessed remarkable growth. Behind every electronic device lies a Printed Circuit Board (PCB), an essential component that connects and supports an array of electronic components. As a leading technology company focused on innovative solutions, our company has recently developed groundbreaking Pcb Classification technology that promises to transform the electronics industry fundamentally. By simplifying manufacturing processes, improving efficiency, and enhancing product reliability, this cutting-edge solution ensures faster and more cost-effective production of high-quality PCBs.1. The Significance of PCB Classification (150 words):PCBs serve as the backbone of modern electronic devices, providing a reliable platform for interconnecting electronic components such as transistors, capacitors, and resistors. With the aim to enhance the performance and functionality of electronic products, our company has invested substantial resources in developing advanced PCB Classification technology.Historically, the PCB manufacturing process relied on manual sorting and classification of components, resulting in time-consuming processes, higher costs, and increased chances of human errors. However, our proprietary technology streamlines and automates this process, leveraging machine learning algorithms to accurately identify and categorize various PCB components within seconds. By efficiently classifying components based on their specifications, our technology reduces production time and costs significantly, ultimately improving the overall productivity of PCB manufacturing.2. Key Features and Benefits of PCB Classification Technology (200 words):Our revolutionary PCB Classification technology is built on a comprehensive dataset of PCB components, encompassing a vast range of industry standards. Leveraging cutting-edge machine learning algorithms, our software analyzes and classifies PCB components based on their unique characteristics, such as size, shape, material, and technical specifications.The key features and benefits of our PCB Classification technology include:a) Improved Efficiency: By automating the classification process, our technology eliminates the need for manual inspection, accelerating the production process. This results in faster turnaround times and allows manufacturers to meet tight deadlines.b) Cost and Resource Optimization: By reducing the need for manual labor involved in traditional classification methods, our technology significantly decreases production costs. Additionally, accurate categorization minimizes waste and enhances resource optimization, thereby improving the overall cost-effectiveness of PCB manufacturing.c) Enhanced Product Reliability: Our PCB Classification technology ensures the accurate selection of components, minimizing the chances of production errors and faulty connections. This leads to improved product reliability, reducing the risk of product recalls and enhancing brand reputation.d) Streamlined Supply Chain: With standardized classification and component identification, our technology facilitates smooth communication and collaboration in the supply chain. By simplifying component sourcing and procurement processes, manufacturers can optimize inventory management and reduce delays.3. Industry Impact and Future Prospects (150 words):The integration of PCB Classification technology is set to revolutionize the electronics industry. As the demand for smaller, more efficient electronic devices continues to grow, efficient and automated PCB manufacturing processes become increasingly crucial. By eliminating inefficiencies and reducing costs, our technology paves the way for the production of affordable and innovative electronic devices.Furthermore, the versatility of our technology allows its application in various sectors such as consumer electronics, telecommunications, automotive, aerospace, and medical devices. As the electronics industry continues to evolve rapidly, our PCB Classification technology empowers manufacturers to keep pace with the industry's demands.In conclusion, our cutting-edge PCB Classification technology represents a significant breakthrough in the electronics industry. By streamlining manufacturing processes, reducing costs, and enhancing product quality, this revolutionary solution has the potential to shape the future of PCB manufacturing and redefine the way electronic devices are produced.

Efficient Turnaround for Prototype PCB: Delivering Quality and Speed

Quick Turn Prototype PCB Company Introduces Cutting-Edge Manufacturing TechnologyWith the increasing demand for high-quality printed circuit board (PCB) products, Quick Turn Prototype PCB Company has responded to the market needs by introducing cutting-edge manufacturing technology. The company has been providing customers with top-notch PCB products for many years, and its latest technology advancements will ensure faster turnaround times, improved designs, and a more streamlined manufacturing process.Quick Turn Prototype PCB is committed to staying ahead of the competition, and their latest investment in new manufacturing equipment and software will allow them to stay at the forefront of the industry. The company has invested in a new, state-of-the-art, automated assembly line to improve its PCB assembly capabilities, further advancing the company's engineering and manufacturing capabilities.In addition to hardware improvements, Quick Turn Prototype PCB has developed powerful software solutions to assist with design and manufacturing processes. The new software allows for more accurate testing and analysis of PCB designs, resulting in faster debugging, improved quality control, and reduced time between prototype and final product iterations.Quick Turn Prototype PCB prides itself on being one of the fastest and most reliable PCB manufacturers in the industry. The company's flagship product is its quick-turn prototype PCB service where customers can receive PCBs within 24 hours of placing an order. Quick Turn Prototype PCB has met the needs of some of the largest tech companies globally and is continuing to expand its customer base around the world.Quick Turn Prototype PCB's manufacturing process is reliable and cost-effective. The company ensures that PCB products are made with the highest quality materials and adhere to strict industry standards. As a result, the company delivers reliable PCB products that enhance the performance and reliability of electronic devices.The Quick Turn Prototype PCB team is made up of experts with extensive experience in the industry. They understand the importance of high-quality PCBs in the manufacturing industry, and their dedication to the highest quality standards is what makes them stand out from the competition.The company has a solid track record of delivering high-quality products, and this has earned it numerous awards and accolades. As part of the company's commitment to customer satisfaction, Quick Turn Prototype PCB offers a comprehensive warranty on all its PCB products.Quick Turn Prototype PCB is also dedicated to improving industry knowledge and skills by providing comprehensive training to its team members. This helps to ensure that everyone in the team is up to date with the latest technological advancements, enabling them to continue providing cutting-edge PCB products to customers.Quick Turn Prototype PCB's commitment to innovation has enabled it to establish an enviable reputation in the PCB manufacturing industry. The company's cutting-edge manufacturing technology and skilled team members ensure that it continues to be an industry leader. Quick Turn Prototype PCB's promise is to manufacture products that meet customer requirements with the highest level of quality and reliability. If you are in need of high-quality PCB products, contact Quick Turn Prototype PCB today for all your PCB manufacturing needs.

Top Manufacturer of Pcb Solder Resist for High-Quality Circuit Board Assembly

Title: Leading Pcb Solder Resist Manufacturer Poised for Unmatched Growth and InnovationIntroduction:In the ever-evolving field of electronics manufacturing, one company has consistently stood out as a leading innovator in the production of Printed Circuit Board (PCB) solder resist solutions. This manufacturer, renowned for its commitment to quality and cutting-edge technology, has continuously raised the bar in the industry, satisfying the demands of customers worldwide. With an extensive range of products combined with advanced manufacturing techniques, the company has positioned itself for unrivaled growth on a global scale.Expanding Product Line:As a frontrunner in the field, this prominent PCB solder resist manufacturer has an impressive array of products tailored to meet the diverse needs of the industry. From single-sided to multilayered PCBs, the company offers customized solder resist solutions that ensure the highest level of quality and reliability. Moreover, with constant research and development efforts, they have successfully introduced new variations of solder resist materials catering to the ever-evolving demands of modern electronics manufacturing.Advanced Manufacturing Techniques:To maintain their industry-leading position, the manufacturer consistently implements state-of-the-art manufacturing techniques throughout their production process. They leverage cutting-edge automation technologies and machinery to ensure precision and efficiency, resulting in solder resist solutions of unparalleled quality. By investing in advanced equipment and continuously upgrading their facilities, the manufacturer highlights their commitment to delivering products with the highest industry standards.Commitment to Environmental Sustainability:In addition to their focus on product excellence, this leading PCB solder resist manufacturer harbors a strong commitment to environmental sustainability. Recognizing the need for eco-friendly alternatives, they have developed a comprehensive range of environmentally-conscious solder resist solutions. These products adhere to strict regulations regarding hazardous substances, minimizing their environmental impact while maintaining the highest performance standards. Through this dedication, the company helps electronics manufacturers operate responsibly and reduce their carbon footprint.Customer-Centric Approach:At the heart of this manufacturer's success lies its dedication to customer satisfaction. By fostering strong relationships with clients, they understand the unique needs of each partner and provide tailored solutions accordingly. Through close collaboration, the manufacturer ensures the delivery of top-tier products that meet or exceed customer expectations. Additionally, their customer support team provides efficient and reliable assistance, helping clients navigate any challenges they may encounter.Global Reach and Market Presence:Owing to their unwavering commitment to quality, innovation, and exceptional customer service, this PCB solder resist manufacturer has established a robust global presence. Their products are widely recognized for their reliability, making the company the brand of choice amongst top electronic manufacturers across the globe. This market presence reflects the confidence and trust that industry leaders place in the manufacturer’s products, further securing their position as a global industry leader.Future Outlook:In an ever-expanding global marketplace, this leading manufacturer remains at the forefront of technological advancements in the PCB solder resist industry. With plans to enhance production capabilities further and continuously invest in research and development, the company aims to solidify its position as an unparalleled innovator. Their future endeavors include the introduction of new, advanced materials, which will shape the future of electronics manufacturing, ensuring their long-lasting success.Conclusion:With an unrivaled commitment to quality, advanced manufacturing techniques, and a customer-centric approach, this PCB solder resist manufacturer continues to set new benchmarks in the industry. Their dedication to eco-friendly solutions, combined with a global market presence, positions them not just as a manufacturer but also as a trusted partner in the evolving world of electronics manufacturing. As they embark on a journey towards unmatched growth and innovation, the industry eagerly awaits the next groundbreaking developments from this leading player.

Comparison of Gold Plating vs Electroless Nickel Immersion Gold (ENIG)

Title: Comparing Two Prominent Circuit Board Finishes: A Case of Hasl vs. EnigIntroduction:In the realm of circuit board manufacturing, the choice of surface finish plays a critical role in determining the performance and reliability of electronic devices. This article aims to explore the two popular finishes - commonly referred to as Hasl and Enig (considered the industry standard in surface finishes, recommended beyond brand names). We will delve into the key features, advantages, and considerations associated with each finish, ensuring that engineers, hobbyists, and electronics enthusiasts make informed decisions for their projects.I. Hasl Finish:Hasl, an acronym for Hot Air Solder Leveling, is a widely used surface finish technique in the electronic manufacturing industry. It involves coating the copper surface with a layer of tin-lead solder, which is then leveled through a hot air process. Let us examine its notable features:1. Cost-Effective: Hasl is widely preferred due to its cost-effectiveness, making it an excellent choice for low to medium volume production runs. Its affordability has made it a popular option for many manufacturers globally.2. Robust and Durable: Due to the thick solder coating, Hasl finish offers excellent protection against oxidization, thus ensuring enhanced durability over time. This makes it ideal for applications exposed to harsh environments or those requiring extended lifecycles.3. Solderability: Hasl is known for its excellent solderability, facilitating easy and reliable soldering of electronic components onto the board surface. The tin-lead solder layer acts as an effective wetting agent, promoting better adhesion and thermal conduction.II. Enig Finish:Electroless Nickel Immersion Gold (Enig) is another widely used surface finish technique that has gained popularity due to its notable advantages. Let us explore the key features associated with this finish:1. Flat Surface and Uniform Thickness: Enig enables a uniform deposition of nickel and gold layers on the copper surface, resulting in a flat and consistent finish. This surface smoothness aids in achieving precise component placement, especially for fine-pitch devices.2. Excellent Solderability: Enig provides excellent solderability and offers superior wetting characteristics required for solder joint formation. The gold layer acts as a protective barrier against oxidization, maintaining solderability even after prolonged storage periods.3. Increased Shelf Life: The gold layer in Enig finish prevents the underlying nickel layer from oxidizing, extending shelf life for the circuit boards. This makes Enig an ideal choice for applications that require longer storage times before assembly.III. Considerations and Recommendations:While both Hasl and Enig finishes have their unique advantages, certain considerations should be taken into account depending on the application requirements:1. Lead-Free Legislation: It is crucial to evaluate the regulatory compliance of each finish with respect to specific regions' lead-free legislation. Hasl, being a tin-lead finish, may not be suitable for applications requiring RoHS compliance.2. Fine-Pitch Devices: Enig's flat surface and precise coating make it more suitable for fine-pitch devices where component placement accuracy is essential. Hasl, due to its relatively thicker solder layer, may hinder placement precision for such devices.3. Environmental Impact: Enig employs gold, a precious metal, which raises concerns regarding its environmental impact. Manufacturers should consider the sustainability aspect when making surface finish choices.Conclusion:In conclusion, the choice between Hasl and Enig surface finishes depends on the specific requirements of the project at hand. Hasl offers cost-effectiveness, robustness, and excellent solderability, while Enig provides a flat surface, uniform thickness, and superior shelf life. Engineers and manufacturers must carefully analyze their needs, regulatory standards, and environmental impact factors to make an informed decision when selecting the appropriate surface finish for their circuit boards.