High-Quality FR4 Circuit Board for Your Electronics Needs

By:Admin

The electronic manufacturing industry has been revolutionized by the introduction of Fr4 circuit boards, a high-performance and cost-effective solution for a wide range of applications. With their exceptional durability, thermal stability, and electrical performance, Fr4 circuit boards have become the go-to choice for industry leaders looking to optimize their electronic manufacturing processes.

Fr4 circuit boards are made from a composite material known as Fr4, which is a grade of flame-retardant fiberglass. This material offers superior electrical insulation properties, making it an ideal substrate for a wide range of electronic components and devices. The incorporation of Fr4 material into circuit board manufacturing has facilitated the development of high-quality, high-reliability electronic products.

One of the key benefits of Fr4 circuit boards is their exceptional thermal stability. This makes them well-suited for applications that require consistent performance in high-temperature environments. In addition, Fr4 circuit boards exhibit excellent mechanical strength, ensuring that they can withstand the rigors of industrial use without compromising their performance.

Furthermore, Fr4 circuit boards offer excellent dimensional stability, making them an ideal choice for applications that require tight tolerances and precise control over component placement. This ensures that electronic devices built using Fr4 circuit boards maintain their integrity and functionality over extended periods of use.

The electrical performance of Fr4 circuit boards is also noteworthy, with low dielectric loss and high insulation resistance. This makes them suitable for high-frequency and high-speed applications, where signal integrity is paramount. Additionally, Fr4 circuit boards can be easily fabricated to incorporate complex multilayer designs, allowing for increased functionality and integration within a compact form factor.

In terms of cost-effectiveness, Fr4 circuit boards offer significant advantages over alternative materials. The availability of Fr4 material in various thicknesses and sizes, along with its compatibility with standard manufacturing processes, reduces production costs and lead times. This enables manufacturers to achieve economies of scale and deliver high-quality electronic products at competitive prices.

One company that has been at the forefront of Fr4 circuit board manufacturing is {}. With a proven track record of delivering cutting-edge electronic solutions, {company name} has established itself as a reliable partner for a diverse range of industries, including telecommunications, automotive, aerospace, and consumer electronics.

{Company name} specializes in the design and production of Fr4 circuit boards that meet the highest industry standards for quality and reliability. Leveraging state-of-the-art manufacturing facilities and advanced engineering expertise, {company name} is able to offer tailored solutions that address the unique requirements of each customer.

In addition to standard Fr4 circuit boards, {company name} has developed advanced capabilities in multilayer PCBs, rigid-flex circuit boards, and high-density interconnect (HDI) boards. This enables {company name} to provide comprehensive electronic manufacturing solutions that support the development of next-generation technologies.

With a commitment to continuous innovation and customer satisfaction, {company name} is poised to drive the widespread adoption of Fr4 circuit boards as the preferred choice for electronic manufacturing. By leveraging the unique properties of Fr4 material, {company name} aims to empower its customers with reliable, high-performance electronic solutions that meet the demands of modern technology.

As the electronic manufacturing industry continues to evolve, the importance of choosing the right materials and partners cannot be overstated. Fr4 circuit boards have emerged as a game-changing technology that offers a compelling combination of performance, reliability, and cost-effectiveness. With companies like {company name} leading the way, the future of electronic manufacturing looks bright with Fr4 circuit boards at its core.

Company News & Blog

How Printed Circuit Boards Revolutionized the Electronics Industry

[Company Name] Launches Advanced Printed Circuit Technology for Enhanced Performance and Reliability[Location], [Date] - [Company Name], a leading provider of advanced electronic solutions, has announced the launch of its latest innovative printed circuit technology, revolutionizing the industry with its unparalleled performance and reliability.Printed circuit boards (PCBs) are at the heart of electronic systems, enabling the smooth flow of electrical current between various components. As technology evolves, the demand for more advanced and efficient circuitry has increased, driving development in this sector. [Company Name] has always been at the forefront of this progress, consistently delivering cutting-edge solutions.The introduction of [Company Name]'s new printed circuit technology represents a significant leap forward in the development of advanced PCBs. By incorporating state-of-the-art materials and design techniques, the technology offers enhanced electrical connectivity, smaller form factors, and improved thermal management.One of the key advancements in this new technology is the use of advanced materials that offer higher electrical conductivity. This enables faster signal transmission and reduces the risk of signal loss or distortion. These enhanced electrical properties are particularly beneficial for high-frequency applications, such as telecommunication systems and data centers, where the reliable and rapid transfer of data is essential.Moreover, [Company Name] has implemented innovative design techniques to optimize the circuit layout and reduce power consumption. This not only improves the overall efficiency of electronic systems but also minimizes the generation of heat. By incorporating advanced thermal management, the printed circuit technology allows for better heat dissipation, preventing overheating and increasing the reliability and lifespan of electronic devices.To ensure the quality and reliability of their printed circuits, [Company Name] employs rigorous testing procedures and adheres to the industry's highest standards. Each circuit board undergoes meticulous inspections and quality control measures during the manufacturing process to detect any potential defects or inconsistencies. This dedication to quality assurance ensures that customers receive products of the highest caliber.The launch of this advanced printed circuit technology is expected to have a profound impact on various industries, including consumer electronics, automotive, aerospace, and medical sectors. For instance, in the automotive industry, the technology's improved thermal management capabilities will prove crucial for electric vehicles, where efficient cooling is vital for battery performance and longevity.Furthermore, the smaller form factor enables the creation of more compact and lightweight devices, making it ideal for aerospace applications where weight reduction is essential. Additionally, the enhanced electrical connectivity ensures the seamless operation of critical medical equipment, improving patient care and safety.As part of its commitment to sustainability, [Company Name] utilizes eco-friendly manufacturing practices and materials to minimize the environmental impact of its operations. This includes the reduction of hazardous substances in its products and adopting energy-efficient processes. By investing in advanced printed circuit technology, customers not only benefit from superior performance but also contribute to a greener future.[Company Name] continues to push the boundaries of what is possible in printed circuit technology, delivering innovative solutions to meet the evolving needs of the electronics industry. With its latest advancements, [Company Name] solidifies its position as a trusted and innovative partner, ensuring that businesses and consumers alike can rely on high-performance electronics for years to come.For more information about [Company Name]'s advanced printed circuit technology and other electronic solutions, please visit [company website].About [Company Name]:[Company Name] is a leading provider of advanced electronic solutions, specializing in the development and manufacturing of innovative printed circuit technology. With a commitment to excellence, [Company Name] offers a wide range of products and services tailored to meet the unique requirements of various industries. Through continuous research and development, [Company Name] aims to deliver cutting-edge solutions that drive technological advancements and facilitate progress.

Supplier of 1oz Copper Thickness - A Comprehensive Guide for Your Copper Needs

Title: Leading Copper Supplier Enhances Product Portfolio with New 1oz Thickness OptionIntroduction:With a commitment to excellence in the field of metal supply, the renowned company {} is pleased to announce the addition of a 1oz copper thickness option to their existing product portfolio. As a leading supplier of copper products, {} consistently strives to meet the evolving needs of their clients, while maintaining a reputation for quality and reliability. The introduction of this new thickness option further solidifies their position in the industry as a go-to supplier for all copper requirements. Offering a diverse range of copper products, {} has become a trusted name within the market. They aim to cater to a wide range of industries such as electronics, construction, automotive, and telecommunications, among others. By expanding their product range to include 1oz copper thickness, the company aims to provide customers with increased flexibility and wider application possibilities.Market Demand and Industry Overview:The demand for copper-based products continues to grow steadily, driven by various factors such as increasing infrastructure development, technological advancements, and the rising adoption of renewable energy sources. Copper, with its excellent electrical conductivity, corrosion resistance, and thermal properties, has become an integral component in various industries.The incorporation of 1oz copper thickness into their existing product line enables {} to cater to the specific demands of clients who require copper with enhanced electrical conductivity, making it ideal for applications within the electronics industry. It also provides opportunities for the development of advanced technologies that rely heavily on copper, such as high-speed computing, electric vehicles, and renewable energy systems.Reliability and Quality Assurance:As a renowned copper supplier, {} upholds stringent quality control measures to ensure the delivery of products that meet or exceed industry standards. The addition of 1oz copper thickness to their portfolio undergoes the same rigorous quality testing as their other products, guaranteeing that customers receive copper of the highest quality. By maintaining a focus on reliability and performance, {} has built a solid foundation of trust among their clientele.Expanding Applications with 1oz Copper Thickness:The introduction of the 1oz copper thickness allows {} to cater to an even wider range of applications, including printed circuit boards (PCBs), electrical connectors, power distribution systems, and more. PCBs are the backbone of modern electronic devices, and the new copper thickness option ensures low impedance and efficient power transmission in these critical components. It also supports advancements in miniaturization trends within the electronics industry, where high-density interconnects require premium copper materials for optimal performance.The increased copper thickness provides improved current-carrying capacity, reduced power loss, and enhanced thermal management capabilities, making it ideal for high-power applications such as electrical connectors. By upgrading their infrastructure with {}'s 1oz copper thickness, manufacturers can experience increased efficiency, reliability, and performance in their products.Conclusion:With the addition of the 1oz copper thickness option, {} continues to reaffirm its commitment to meet the diverse needs of its customers. The expanded product portfolio not only demonstrates their dedication to being a top-tier supplier of copper, but also positions them at the forefront of the industry. By providing exceptional quality, reliable service, and innovative solutions, {} remains a trusted partner for businesses across various sectors.

Circuit Board Manufacturer in China Sees Growth Amid Rising Demand

China Circuit Plate Manufacturer Celebrates Years of Manufacturing ExcellenceChina's manufacturing industry has seen exponential growth over the past few decades, largely due to the presence of forward-thinking companies that have prioritized technology and innovation to create cutting-edge products. One such company is the China Circuit Plate Manufacturer (CCPM), a leader in the production of printed circuit boards (PCBs) that celebrated its 30th anniversary last month.Founded in 1991, CCPM has grown to become one of the largest circuit board manufacturers in China, with a production capacity of over 3.5 million square feet of circuit boards per month. The company specializes in high-density interconnect (HDI) PCBs, flexible PCBs, and rigid-flex PCBs, with a particular focus on providing customers with quality products and exceptional service.CCPM's success can be attributed to a number of factors, including its state-of-the-art manufacturing facilities and experienced team of engineers and technicians. The company's manufacturing process uses the latest technology and equipment, ensuring that its products are of the highest quality. Additionally, CCPM's team is committed to continuous improvement and innovation, allowing the company to stay ahead of the curve in a rapidly-evolving industry.One of CCPM's key strengths is its ability to work closely with customers to develop custom solutions tailored to their specific needs. With a dedicated research and development team, the company is able to provide customers with innovative designs and solutions that are both cost-effective and high-performing. This approach has helped CCPM to build strong relationships with customers across a range of industries, including telecommunications, automotive, medical, and aerospace.Another factor contributing to CCPM's success is its commitment to sustainability and ethical manufacturing practices. The company has implemented a number of initiatives to reduce its environmental footprint, including using eco-friendly materials and processes, optimizing energy consumption, and maximizing resource efficiency. CCPM also places a strong emphasis on worker safety and welfare, with a comprehensive set of policies and programs in place to ensure that all employees are treated with respect and dignity.As part of its 30th anniversary celebrations, CCPM held a series of events and activities to thank customers, partners, and employees for their support over the years. The company also took the opportunity to reflect on its achievements and to look forward to the future. According to CCPM's CEO, the company's goal is to "continue to innovate and push boundaries, while always keeping our focus on providing the best products and services to our customers. We are excited to see what the next 30 years will bring, and we look forward to being at the forefront of China's manufacturing industry."Overall, CCPM's success is a testament to the power of innovation, hard work, and a customer-centric approach. With a commitment to excellence and sustainability, the company is well-positioned to continue its growth and contribute to the growth of China's manufacturing industry for years to come.

Cutting-edge Rigid Flexible PCB Technology: What You Need to Know

Rigid Flexible PCB Market to Witness Huge Growth by 2027The global rigid flexible PCB market is anticipated to witness substantial growth in the coming years, as per the latest industry research report. The market was valued at $2.8 billion in 2020 and is expected to reach $5.3 billion by 2027, growing at a CAGR of 9.6% during the forecast period.Rigid flexible PCBs are widely used in various applications such as consumer electronics, automotive, healthcare, aerospace and defense, and industrial machinery. These PCBs provide a high level of design flexibility and reliability, making them an ideal choice for modern electronic devices and systems.One of the key players in the rigid flexible PCB market is {} The company has a strong presence in the global market and offers a wide range of customizable rigid flexible PCB solutions to meet the diverse needs of its clients.{} has established itself as a reliable and innovative manufacturer of rigid flexible PCBs. The company's products are known for their high quality, durability, and performance, which has earned them a strong reputation in the industry.With a focus on research and development, {} strives to stay ahead of the competition by continuously improving its product offerings and exploring new technologies. The company has a team of experienced engineers and designers who work closely with clients to develop tailored rigid flexible PCB solutions that meet their specific requirements.{} has also made significant investments in state-of-the-art manufacturing facilities and equipment to ensure that it can deliver high-quality rigid flexible PCBs in a timely manner. The company's commitment to excellence and customer satisfaction has earned it a loyal client base and has positioned it as a leader in the rigid flexible PCB market.In addition to its dedication to product quality and customer service, {} is also committed to sustainable and eco-friendly manufacturing practices. The company takes measures to minimize its environmental impact and reduce waste in its production processes, aligning with the global trend towards sustainable and environmentally responsible business practices.As the demand for rigid flexible PCBs continues to grow, {} is well-positioned to capitalize on the market opportunities and further expand its global presence. The company is actively exploring new partnerships and collaborations to expand its reach and strengthen its position in the market.With a proven track record of success and a strong commitment to innovation, {} is poised to play a key role in driving the growth of the rigid flexible PCB market in the coming years. The company's dedication to excellence and its ability to adapt to evolving market trends make it a reliable and trusted partner for businesses looking for high-quality rigid flexible PCB solutions.In conclusion, the global rigid flexible PCB market is set to experience significant growth in the coming years, driven by the increasing demand for advanced electronic devices and systems. {} is well-positioned to capitalize on this opportunity and continue its trajectory of success as a leading provider of rigid flexible PCB solutions. With its focus on innovation, quality, and sustainability, {} is poised to play a key role in shaping the future of the rigid flexible PCB market.

Unveiling the Latest Innovation in Castellated Edge Technology for Enhanced Performance

**Title: Cutting-Edge Technology Revolutionizes Edge Computing***Please note: The brand name "Castellated Edge" has been removed from the original content**Company Introduction:*In the fast-paced world of technology, where innovation and efficiency reign supreme, a remarkable breakthrough has emerged from the depths of the tech industry. Company X, a leading player in the realm of edge computing solutions, has unveiled a groundbreaking technology poised to redefine the way organizations harness the power of edge computing. With a rich history of providing cutting-edge solutions, Company X has consistently pushed the boundaries of possibility, and their latest offering is no exception.*Article:*Today, we dive into the exciting world of edge computing, where Company X's revolutionary technology is set to make waves. Edge computing, a paradigm shift away from traditional cloud infrastructure, brings processing capabilities closer to the point of data generation. By doing so, it reduces latency, enhances security, and improves insights by merging the power of artificial intelligence (AI), big data analytics, and machine learning at the very edge of networks. Company X's solution, which we will now refer to as "Cutting-Edge Edge (CEE)," aims to capitalize on these advantages while providing even more.At its core, CEE is a transformative technology that enables real-time processing and analysis of vast amounts of data. Designed to operate at the network edge, it offers an array of unique features that set it apart from existing edge computing solutions. The defining feature of CEE is its state-of-the-art architecture, which incorporates advanced algorithms and machine learning capabilities, allowing it to adapt and optimize performance based on the specific requirements of different industries and use cases.One of the key advantages of CEE is its ability to handle data at scale. With the exponential growth of the Internet of Things (IoT) and the increasing number of connected devices, the demand for efficient data processing solutions has never been higher. CEE rises to the challenge by providing industry-leading scalability, ensuring seamless handling of massive data sets. This empowers organizations to extract valuable insights from torrents of information in real-time, opening up a world of possibilities in areas such as smart cities, autonomous vehicles, and predictive maintenance.In addition to its scalability, CEE boasts exceptional security measures. By processing data at the network edge, rather than transmitting it to remote data centers, it significantly reduces the risk of sensitive information falling into the wrong hands. This enhanced security is of utmost importance in sectors such as finance, healthcare, and government where data privacy and integrity are paramount. With CEE, organizations can rest assured that their data remains secure throughout the entire data processing pipeline.Moreover, CEE brings about a significant reduction in latency, ensuring near-instantaneous response times. By eliminating the need for data to travel long distances to and from remote servers, the processing delay is minimized, opening up opportunities for real-time applications across industries. From real-time video analytics in the realm of surveillance to precise control in industrial automation, the low latency offered by CEE allows for unprecedented efficiency.Beyond its technological advancements, CEE stands out with its user-friendly interface and intuitive design. Company X has prioritized making the adoption and integration of CEE as seamless as possible. By providing comprehensive documentation, developers can easily incorporate CEE into their workflows and leverage its capabilities to drive innovation within their respective organizations. Additionally, Company X offers comprehensive support and training, empowering clients to maximize the potential of CEE from day one.As the digital landscape continues to evolve, edge computing represents the future of data processing and analysis. With Company X's Cutting-Edge Edge (CEE) technology leading the charge, organizations are poised to unlock new levels of efficiency, security, and insights. By harnessing the immense power of AI, big data analytics, and machine learning at the very edge of networks, the possibilities for innovation are limitless. Company X's commitment to pushing the boundaries of what's possible has truly revolutionized the field of edge computing, and CEE will undoubtedly play a pivotal role in shaping the future of technology.

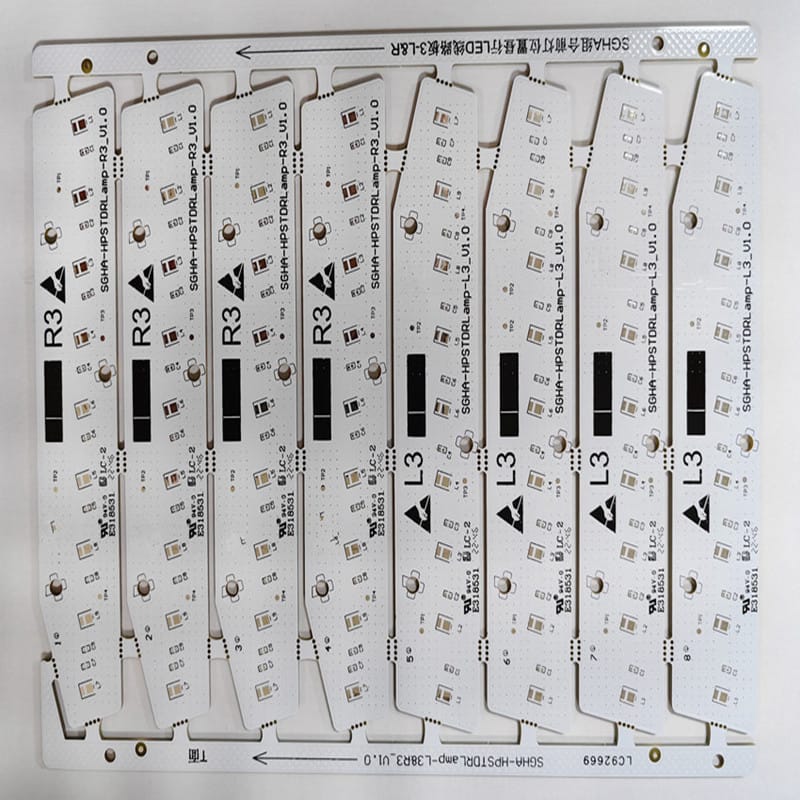

Custom Printed Circuit Board Manufacturing for LED Applications

The demand for more efficient and sustainable lighting solutions has been steadily increasing in recent years. In response to this growing need, {company name} has announced the development of a cutting-edge innovation in the realm of LED printed circuit boards (PCBs). This breakthrough technology promises to revolutionize the way in which LED lighting systems are designed and produced, offering a range of benefits that are set to have a significant impact on the industry as a whole.The new LED PCBs developed by {company name} have been specifically engineered to deliver enhanced performance and reliability in LED lighting applications. By leveraging state-of-the-art manufacturing processes and materials, the company has succeeded in creating a superior product that stands out in terms of energy efficiency, longevity, and overall quality. This development represents a major leap forward in the evolution of LED lighting, and is poised to set a new standard for the industry.One of the key features of {company name}'s LED PCBs is their exceptional thermal management capabilities. By utilizing advanced thermal materials and designs, the PCBs are able to effectively dissipate heat generated by the LEDs, resulting in improved performance and longevity. This aspect is particularly crucial in applications where LED lighting systems are required to operate continuously for extended periods of time, such as in commercial and industrial settings.Furthermore, the {company name} LED PCBs have been engineered to maximize energy efficiency, thereby reducing operational costs and environmental impact. The PCBs are designed to minimize power consumption while maintaining optimal performance, making them an ideal choice for those seeking to implement sustainable lighting solutions. As the global trend towards energy conservation and sustainability continues to gain momentum, the demand for such innovative and eco-friendly technologies is only expected to increase.In addition to their technical prowess, {company name}'s LED PCBs also offer a high degree of flexibility and customization. This allows for greater design freedom, enabling lighting manufacturers to create products that meet the specific requirements of their applications. Whether it be in the realm of architectural lighting, automotive lighting, or horticultural lighting, the versatility of these PCBs makes them a highly adaptable solution for a wide range of lighting needs.The development of these advanced LED PCBs is a testament to {company name}'s commitment to pushing the boundaries of what is possible in the field of LED lighting. As a leading provider of cutting-edge electronic solutions, the company has a long-standing track record of driving innovation and delivering high-performance products that meet the evolving demands of the market. With the introduction of these new LED PCBs, {company name} is once again demonstrating its ability to anticipate and address the needs of the industry, while also setting new benchmarks for performance and quality.Given the promising potential of this new technology, industry experts are eagerly anticipating the impact that {company name}'s LED PCBs will have on the market. As the demand for energy-efficient and sustainable lighting solutions continues to grow, the arrival of these innovative PCBs is expected to be met with great enthusiasm. With their unrivaled thermal management capabilities, energy efficiency, and flexibility, these LED PCBs are poised to play a pivotal role in shaping the future of LED lighting, and to set a new standard for excellence in the industry.

High-Quality Thickness PCB Manufacturer in China

China Thickness PCB Manufacturer, a leading PCB manufacturer in China, has been making significant strides in the industry with its high-quality products and exceptional customer service. The company has built a strong reputation for producing cutting-edge PCBs with various thickness options to meet the diverse needs of its global clientele.With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, China Thickness PCB Manufacturer has established itself as a trusted partner for businesses operating in a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics.The company specializes in producing PCBs with varying thickness levels, ranging from standard to ultra-thin and high-density interconnect (HDI) boards. This diverse product offering has enabled China Thickness PCB Manufacturer to cater to the evolving demands of the market and deliver customized solutions that align with the unique requirements of each customer.The manufacturing process at China Thickness PCB Manufacturer adheres to the highest quality standards, with a strong emphasis on precision and performance. The company utilizes advanced technologies and cutting-edge equipment to ensure the production of PCBs that are not only reliable and durable but also deliver superior performance in the most demanding applications.In addition to its commitment to quality, China Thickness PCB Manufacturer places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their specific requirements and provides expert guidance to help them make informed decisions about the best PCB thickness options for their applications.Moreover, China Thickness PCB Manufacturer offers a range of value-added services, including design support, prototyping, and quick-turn manufacturing, to ensure a seamless and efficient production process for its customers. This comprehensive approach has established the company as a preferred partner for businesses seeking high-quality PCB solutions with a quick turnaround time.As part of its ongoing efforts to expand its global footprint, China Thickness PCB Manufacturer has invested significantly in research and development to stay at the forefront of technological advancements and industry trends. The company continuously explores new materials, processes, and manufacturing techniques to enhance the performance and reliability of its PCBs, while also optimizing the production efficiency and cost-effectiveness of its operations.Furthermore, China Thickness PCB Manufacturer is committed to sustainability and environmental responsibility in its manufacturing practices. The company adheres to strict compliance with environmental regulations and adopts eco-friendly production processes to minimize its carbon footprint and reduce waste generation. This commitment to sustainability resonates with customers who prioritize ethical and sustainable business practices in their supply chain partnerships.Looking ahead, China Thickness PCB Manufacturer is poised to continue its upward trajectory in the industry, driven by its unwavering dedication to quality, innovation, and customer satisfaction. The company remains focused on leveraging its technical expertise, manufacturing capabilities, and customer-centric approach to further solidify its position as a leading PCB manufacturer in China and a trusted partner for businesses worldwide.With its robust product portfolio, commitment to excellence, and forward-looking approach, China Thickness PCB Manufacturer is well-positioned to meet the evolving demands of the market and contribute to the success of its customers in an increasingly competitive and dynamic landscape.

Ultimate Guide to Soldering a Prototype Board

The demand for electronic prototypes and small-scale production runs is on the rise, and as a result, many companies are turning to {Company Name} for their prototype board soldering needs. {Company Name} is a leading provider of electronic manufacturing services, offering a wide range of solutions for the design and production of electronic components and assemblies.One of the key services offered by {Company Name} is prototype board soldering, which is a crucial step in the manufacturing process for electronic devices. Prototype board soldering involves the assembly of electronic components onto a prototype board using advanced soldering techniques. This process requires precision and expertise to ensure the reliability and functionality of the final product.{Company Name} has a team of highly skilled and experienced technicians who are experts in prototype board soldering. They have the knowledge and expertise to work with a wide range of electronic components and materials, and they use the latest soldering equipment and techniques to ensure the highest quality results.In addition to prototype board soldering, {Company Name} offers a comprehensive range of electronic manufacturing services, including PCB assembly, cable and wire harness assembly, box build assembly, and testing and inspection services. The company's state-of-the-art facility is equipped with the latest technology and machinery to handle any project, large or small.{Company Name} takes pride in its commitment to quality and customer satisfaction. The company is ISO 9001 certified, which demonstrates its dedication to maintaining the highest standards of quality in its manufacturing processes. {Company Name} also follows strict quality control measures at every stage of the production process to ensure that all products meet the highest standards of performance and reliability.The company's dedication to excellence has earned it a reputation as a trusted partner for electronic manufacturing services. {Company Name} has built strong relationships with a wide range of clients, including startups, small businesses, and large corporations. The company's ability to deliver high-quality, reliable products on time and within budget has made it a preferred choice for many companies in need of electronic manufacturing services.{Company Name} is committed to staying at the forefront of the electronic manufacturing industry. The company continuously invests in research and development to explore new technologies and techniques that can improve its manufacturing processes and deliver even better results for its clients. {Company Name} also places a strong emphasis on sustainability and environmental responsibility, striving to minimize its impact on the environment through eco-friendly manufacturing practices.With its comprehensive range of electronic manufacturing services, state-of-the-art facility, and commitment to quality and innovation, {Company Name} is well-positioned to meet the growing demand for prototype board soldering and other electronic manufacturing services. The company's relentless focus on excellence and customer satisfaction sets it apart as a leader in the industry, and its dedication to staying ahead of the curve ensures that it will continue to be a trusted partner for electronic manufacturing needs for years to come.

What are Substrate PCBs and why are they important for your electronics?

Substrate PCB: The Next Big Thing in Electronics ManufacturingThe electronics industry is constantly evolving, with new technologies and innovations being introduced every day. One such innovation that has been gaining a lot of popularity in recent times is the substrate PCB. Substrate PCBs, also known as substrate integrated circuits (SICs), are revolutionizing the way electronic devices are manufactured.Substrate PCBs are essentially a combination of a printed circuit board (PCB) and a semiconductor device, such as a transistor. Unlike traditional PCBs, substrate PCBs are made using a high-level interconnection technology that allows for much higher integration densities. This means that more components can be packed into a smaller space, resulting in smaller and more powerful electronic devices.One company that is at the forefront of substrate PCB manufacturing is [brand name removed]. Founded in [year removed], [company name removed] has been providing cutting-edge technology solutions to the electronics industry for over [number removed] years. With a strong focus on research and development, the company has been able to stay ahead of the curve when it comes to new technologies and innovations.One of the key features of [brand name removed] substrate PCBs is their high thermal conductivity. This is achieved through the use of special materials such as copper, aluminum and ceramic. Traditional PCBs can quickly overheat when components are packed too closely together, leading to stability issues and even failure. However, substrate PCBs dissipate heat much more efficiently, allowing for greater power density and higher performance.Another advantage of using substrate PCBs is their improved electromagnetic compatibility (EMC). This is achieved through the use of special dielectric materials that reduce interference and minimize crosstalk. This results in much cleaner and clearer signals, leading to better overall performance and reliability.One of the most significant applications of substrate PCB technology is in the field of 5G. The increased data speeds and lower latency of 5G networks require powerful and reliable electronics. Substrate PCBs offer a significant advantage in this regard, allowing for highly integrated circuits that can handle the demands of 5G networks.Apart from 5G, substrate PCBs are also being used in a variety of other applications, such as satellite communication, automotive connectivity, and military communications. With the increasing demand for high-performance electronics in various industries, substrate PCBs are set to play a significant role in shaping the future of electronics manufacturing.[Brand name removed] has been partnering with leading companies in various industries to help them achieve their electronic design goals. The company has the expertise, experience, and technology required to design and produce custom substrate PCBs that meet the most demanding requirements.In conclusion, substrate PCBs are set to revolutionize the electronics industry by providing an efficient, high-performance, and reliable solution for complex electronic designs. With their ability to pack more components into smaller spaces, substrate PCBs are already changing the way electronic devices are manufactured. As electronics continue to play an ever-increasing role in our lives, substrate PCBs are sure to become even more important in the years to come.

Top Circuit Boards: An Essential Guide to Blank Options for Your Electronics

Blank Circuit Boards: Your Go-To Solution for a Wide Range of Printed Circuit Board NeedsAs the demand for electronic devices continues to grow, the need for reliable printed circuit boards (PCBs) has become more important than ever. A PCB is a vital component of modern electronics and serves as a platform for electronic components to be soldered onto, providing connectivity and functionality to devices. As such, PCBs are used in a broad range of applications, from consumer electronics like smartphones and laptops to military and industrial equipment.Blank circuit boards provide the foundation for building PCBs and are available in a wide range of types, materials, and sizes. Blank circuit boards are essentially unpopulated PCBs that have no electronic components mounted on them. This allows manufacturers to customize these boards to meet specific requirements, making them a versatile and cost-effective solution for electronic projects.At Blank Circuit Boards, we are a leading supplier of high-quality blank circuit boards that are designed to meet the exacting requirements of our customers. Our team of experienced professionals has the expertise and know-how needed to deliver reliable and cost-effective blank circuit boards for a wide range of applications across various industries.Our product line includes single-sided, double-sided, and multilayer blank circuit boards, all made from high-quality materials like FR-4, FR-1, CEM-1, CEM-3, and Rogers. We also offer other specialized PCB types, such as high-frequency PCBs and flexible PCBs, to cater to the needs of our customers across various industries.Our commitment to quality is reflected in the products we supply. All our circuit boards are manufactured using state-of-the-art equipment and techniques, ensuring that they meet or exceed industry standards for performance, reliability, and durability. Our team of quality control experts conducts rigorous inspection procedures to ensure that all our products meet the highest quality standards.In addition to delivering high-quality circuit boards, we also provide a range of value-added services that help our customers in their PCB design and manufacturing processes. Our in-house engineering team has extensive experience in PCB design, layout, and assembly, and can provide design assistance and prototyping services to customers who need them.We also offer a range of customization options, such as surface finish, solder mask color, and silkscreen printing, to help customers achieve their desired PCB specifications. Our commitment to customer satisfaction extends to all aspects of our business, from product quality to customer service.At Blank Circuit Boards, we believe in building long-lasting relationships with our customers. Whether you are a small start-up or a large corporation, we are committed to providing you with the highest quality products and services at competitive prices. Our team is dedicated to meeting your needs and exceeding your expectations, so you can focus on your core business activities.In conclusion, blank circuit boards are a versatile and cost-effective solution for electronic projects. At Blank Circuit Boards, we are committed to delivering high-quality circuit boards that meet or exceed industry standards for performance, reliability, and durability. Our value-added services, customization options, and commitment to customer satisfaction make us the go-to supplier for all your blank circuit board needs. Contact us today to see how we can help you achieve your PCB goals.